Ka a na-eji ndị na-eduzi aluminom na-emewanye ihe na-arụ ọrụ wiwi ụgbọ ala, isiokwu a na-enyocha ma na-ahazi nkà na ụzụ njikọ nke aluminom ike wiring harnesses, na-enyocha ma na-atụle arụmọrụ nke ụzọ njikọ dị iche iche iji mee ka nhọrọ nke aluminom na-emecha nweta ụzọ njikọ njikọ.

01 Nchịkọta

Site n'ịkwalite ngwa nke ndị na-eduzi aluminom na wiwi ụgbọ ala, iji ndị na-eduzi aluminom kama ndị na-eduzi ọla kọpa omenala na-eji nwayọọ nwayọọ na-abawanye. Otú ọ dị, na ngwa ngwa nke aluminom wires dochie ọla kọpa wires, electrochemical corrosion, elu okpomọkụ creep, na conductor oxidation bụ nsogbu ndị a ga-eche ihu na dozie n'oge ngwa ngwa. N'otu oge ahụ, ngwa nke wires aluminum na-edochi ọla kọpa ga-enwerịrị ihe achọrọ nke waya ọla kọpa mbụ. Ngwa eletriki na akụrụngwa iji zere mmebi arụmọrụ.

Iji dozie nsogbu ndị dị ka electrochemical corrosion, elu okpomọkụ creep, na conductor oxidation n'oge ngwa nke aluminum wires, e nwere ugbu a anọ mainstream njikọ ụzọ na ụlọ ọrụ, bụ: esemokwu ịgbado ọkụ na nrụgide ịgbado ọkụ, esemokwu ịgbado ọkụ, ultrasonic welding, na plasma ịgbado ọkụ.

Ihe na-esonụ bụ nyocha na ntụle arụmọrụ nke ụkpụrụ njikọ na nhazi nke ụdị njikọ anọ a.

02 Mgbado ọkụ nke esemokwu na ịgbado ọkụ

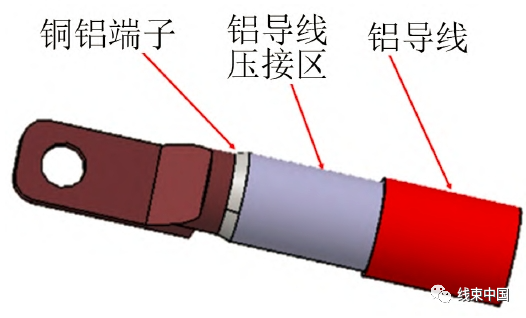

Ịgbado ọkụ nke esemokwu na njikọ nrụgide, buru ụzọ were mkpanaka ọla kọpa na mkpanaka aluminom maka ịgbado esemokwu, wee tinye stampụ ọla kọpa iji mepụta njikọ eletrik. A na-eji ígwè aluminom eme ihe ma kpụzie ya ka ọ bụrụ njedebe nke aluminom, a na-emepụtakwa ọla kọpa na aluminom. Mgbe ahụ, a na-etinye waya aluminom n'ime njedebe aluminum crimping nke ọla kọpa-aluminom ọnụ na hydraulically crimped site omenala waya crimping akụrụngwa iji mezue njikọ n'etiti aluminom eduzi na ọla kọpa-aluminom ọnụ, dị ka e gosiri na Figure 1.

Tụnyere ụdị njikọ ndị ọzọ, ịgbado ọkụ esemokwu na ịgbado ọkụ na-etolite mpaghara mgbanwe ọla kọpa-aluminom site na ịgbado ọkụ nke mkpanaka ọla kọpa na mkpanaka aluminom. N'elu ịgbado ọkụ bụ otu na oke, na-ezere nke ọma nsogbu okpomọkụ creep nke dị iche iche okpomọkụ mgbasa coefficients nke ọla kọpa na aluminum. , Tụkwasị na nke ahụ, nhazi nke mpaghara mgbanwe alloy na-ezerekwa corrosion electrochemical nke na-eme ka ọrụ metal dị iche iche dị n'etiti ọla kọpa na aluminom. A na-eji tubes na-ekpo ọkụ na-emechi emechi akara na-ekewapụ nnu nnu na vapor mmiri, nke na-ezerekwa ihe omume nke corrosion electrochemical nke ọma. Site na hydraulic crimping nke aluminom waya na aluminom crimp njedebe nke ọla kọpa-aluminom ọnụ, monofilament Ọdịdị nke aluminum conductor na oxide oyi akwa na n'ime mgbidi nke aluminum crimp ọgwụgwụ na-ebibi na peeled, na mgbe oyi na-agwụ n'etiti otu wires na n'etiti aluminum conductor conductor na n'ime ime mgbidi nke crimp. Ngwakọta ịgbado ọkụ na-eme ka arụ ọrụ eletriki nke njikọ ahụ dịkwuo mma ma na-enye ọrụ arụmọrụ kachasị ntụkwasị obi.

03 ịgbado ọkụ esemokwu

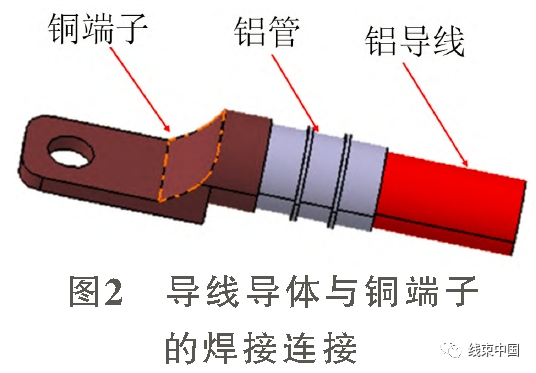

Mgbado ọkụ nke esemokwu na-eji tube aluminom na-akpụkọ ma na-akpụzi onye na-eduzi aluminom. Mgbe ebipụchara ihu njedebe, a na-eji ọnụ ọla kọpa arụ ọrụ ịgbado ọkụ. A na-emecha njikọ ịgbado ọkụ n'etiti onye na-eduzi waya na ọdụ ọla kọpa site na ịgbado ọkụ esemokwu, dịka egosiri na eserese 2.

Mgbado ọkụ esemokwu na-ejikọ waya aluminom. Nke mbụ, a na-etinye tube aluminom na onye na-eduzi waya aluminom site na crimping. Ihe owuwu monofilament nke onye na-eduzi na-eme ka ọ bụrụ plastik site na crimping iji mepụta akụkụ okirikiri okirikiri siri ike. Mgbe ahụ, a na-echigharị akụkụ nke ịgbado ọkụ site n'ịtụgharị iji mezue usoro ahụ. Nkwadebe nke ịgbado ọkụ n'elu. Otu njedebe nke ọnụ ụzọ ọla kọpa bụ usoro njikọ eletriki, na njedebe nke ọzọ bụ njikọ njikọta nke elu ọla kọpa. The ịgbado ọkụ njikọ elu nke ọla kọpa ọnụ na ịgbado ọkụ n'elu nke aluminum waya na-welded na jikọọ site esemokwu ịgbado ọkụ, na mgbe ahụ ịgbado ọkụ flash na-ebipụ na ekara iji mezue njikọ njikọ nke esemokwu ịgbado ọkụ aluminum waya.

Tụnyere ụdị njikọ ndị ọzọ, ịgbado ọkụ esemokwu na-etolite njikọ mgbanwe n'etiti ọla kọpa na aluminom site na ịgbado ọkụ n'etiti ọdụ ọla kọpa na waya aluminom, na-ebelata corrosion electrochemical nke ọla kọpa na aluminom nke ọma. Mpaghara mgbanwe mgbanaka mgbado ọkụ ọla kọpa-aluminom jiri tubing na-ekpo ọkụ na-ekpo ọkụ mechie n'ọkwa ikpeazụ. A gaghị ekpuchi ebe ịgbado ọkụ na ikuku na mmiri, na-ebelata corrosion ọzọ. Tụkwasị na nke ahụ, ebe ịgbado ọkụ bụ ebe onye na-eduzi waya aluminom na-ejikọta ya na njedebe ọla kọpa site na ịgbado ọkụ, nke na-eme ka ike ịdọrọ nke nkwonkwo na-eme ka ọ dị mfe.

Otú ọ dị, ọghọm dịkwa na njikọ n'etiti aluminum wires na ọla kọpa-aluminom ọnụ ọnụ ọgụgụ 1. Ngwa nke esemokwu ịgbado ọkụ ka waya njikota emepụta chọrọ iche iche pụrụ iche esemokwu ịgbado ọkụ akụrụngwa, nke nwere ogbenye versatility na-abawanye na ego na ofu akụ nke waya njikota emepụta. Nke abuo, na esemokwu ịgbado ọkụ N'oge usoro, monofilament Ọdịdị nke waya bụ kpọmkwem esemokwu welded na ọla kọpa ọnụ, na-akpata cavities na esemokwu ịgbado ọkụ mpaghara ebe. Ọnụnọ nke uzuzu na ihe ndị ọzọ na-adịghị ọcha ga-emetụta àgwà ịgbado ọkụ ikpeazụ, na-eme ka enweghị ike na-arụ ọrụ na eletriki nke njikọ ịgbado ọkụ.

04 Ultrasonic ịgbado ọkụ

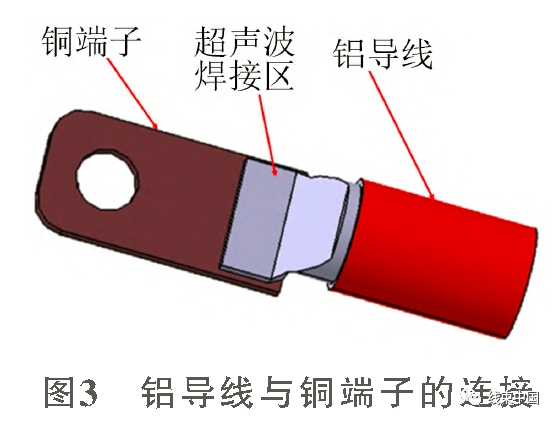

Ultrasonic ịgbado ọkụ nke aluminum wires na-eji ultrasonic welding akụrụngwa jikọọ aluminum wires na ọla kọpa ọnụ. Site na oscillation dị elu nke isi ịgbado ọkụ nke ultrasonic welding akụrụngwa, aluminom waya monofilaments na aluminum wires na ọla kọpa ọnụ na-ejikọta ọnụ iji mechaa aluminum waya na njikọ nke ọla kọpa ọnụ na-egosi na Figure 3.

Njikọ ịgbado ọkụ nke Ultrasonic bụ mgbe wires aluminom na ọnụ ụzọ ọla kọpa na-ama jijiji na ebili mmiri ultrasonic dị elu. Vibration na esemokwu n'etiti ọla kọpa na aluminom mejupụta njikọ dị n'etiti ọla kọpa na aluminom. N'ihi na ma ọla kọpa na aluminom nwere ihu na-eche ihu cubic metal kristal Ọdịdị, na a elu-ugboro oscillation gburugburu ebe obibi N'okpuru ọnọdụ a, Atọm nnọchi n'ime metal crystal Ọdịdị na-mechara na-etolite alloy mgbanwe oyi akwa, n'ụzọ dị irè na-ezere omume nke electrochemical corrosion. N'otu oge ahụ, n'oge usoro ịgbado ọkụ ultrasonic, a na-ehichapụ oyi akwa oxide n'elu nke aluminom conductor monofilament, mgbe ahụ, njikọ ịgbado ọkụ n'etiti monofilaments na-agwụcha, nke na-eme ka ọkụ eletrik na arụ ọrụ nke njikọ ahụ dịkwuo mma.

E jiri ya tụnyere ụdị njikọ ndị ọzọ, ultrasonic ịgbado ọkụ akụrụngwa bụ ihe a na-ejikarị eme ihe maka ndị na-emepụta eriri waya. Ọ dịghị achọ itinye ego ọhụrụ etinyere. N'otu oge ahụ, ọnụ ụzọ na-eji ọla kọpa stampụ akara, na ọnụ ahịa ọnụ ala dị ala, ya mere ọ nwere uru kachasị mma. Agbanyeghị, ọghọm dịkwa. E jiri ya tụnyere ụdị njikọ ndị ọzọ, ultrasonic welding nwere ihe na-esighi ike na-arụ ọrụ na nkwụsi ike na-adịghị mma. Ya mere, a naghị atụ aro iji njikọ ịgbado ọkụ ultrasonic na mpaghara ịma jijiji dị elu.

05 Plasma ịgbado ọkụ

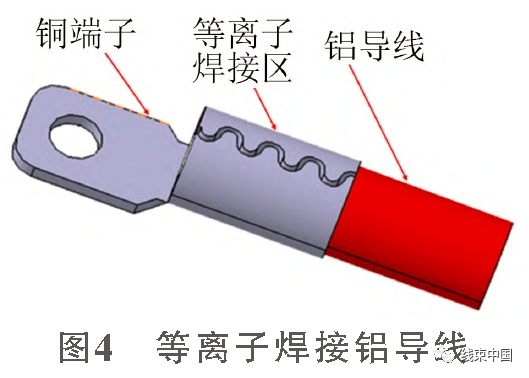

Plasma ịgbado ọkụ na-eji ọnụ ọla kọpa na aluminom wires maka crimp njikọ, na mgbe ahụ site na-agbakwụnye solder, plasma arc na-eji irradiate na ikpo ebe a ga-welded, gbazee solder, jupụta ebe ịgbado ọkụ, na-mezue njikọ aluminum waya, dị ka e gosiri na Figure 4.

Plasma nke ndị na-eduzi aluminom na-ebu ụzọ mee welding plasma nke ọnụ ụzọ ọla kọpa, a na-emecha crimping na ntinye nke ndị na-eduzi aluminom site na mkpọ. Ngwunye ịgbado ọkụ plasma na-etolite ihe dị ka gbọmgbọm mgbe emechara ya, wee mejupụta ebe ịgbado ọkụ nke nwere zinc, na njedebe crimped bụ Tinye ihe nwere zinc. N'okpuru irradiation nke plasma arc, a na-ekpo ọkụ na-agbaze nke zinc na-agbaze, wee banye na oghere waya na mpaghara crimping site na capillary edinam iji mezue usoro njikọ nke ọnụ ụzọ ọla kọpa na aluminom wires.

Plasma welding aluminum wires mezuo njikọ ngwa ngwa n'etiti wires aluminom na ọdụ ọla kọpa site na crimping, na-enye akụrụngwa a pụrụ ịdabere na ya. N'otu oge ahụ, n'oge crimping usoro, site na mkpakọ ruru 70% ka 80%, mbibi na peeling pụọ nke oxide oyi akwa nke onye nduzi na-agwụ agwụ, rụọ ọrụ nke ọma eletriki arụmọrụ, belata kọntaktị iguzogide nke njikọ njikọ, na-egbochi kpo oku nke njikọ. Mgbe ahụ, tinyezie ihe na-ere ihe nwere zinc na njedebe nke ebe a na-akpachapụ anya, ma jiri eriri plasma mee ka ọkụ na-ekpo ọkụ ma kpoo ebe a na-agbado ọkụ. A na-ekpo ọkụ ma gbazee ihe na-ere ihe nke nwere zinc, na ihe na-ere ya na-ejupụta oghere dị na ebe a na-eme ihe site na capillary, na-enweta mmiri na-agba nnu na mpaghara crimping. Mwepu dị iche iche na-ezere ọnọdụ corrosion electrochemical. N'otu oge ahụ, n'ihi na onye na-ere ahịa dịpụrụ adịpụ ma na-echekwa ya, a na-emepụta mpaghara mgbanwe, nke na-ezere nke ọma ihe omume nke na-ekpo ọkụ na-ekpo ọkụ ma na-ebelata ihe ize ndụ nke ịba ụba njikọ njikọ n'okpuru ọkụ ọkụ na oyi. Site na ịgbado ọkụ plasma nke mpaghara njikọ, a na-emeziwanye arụmọrụ eletriki nke mpaghara njikọ nke ọma, a na-emeziwanyekwa akụrụngwa nke mpaghara njikọ.

E jiri ya tụnyere ụdị njikọ ndị ọzọ, ịgbado ọkụ plasma na-ekewapụ ọdụ ọla kọpa na ndị na-eduzi aluminom site na oyi akwa mgbanwe mgbanwe na oyi akwa ịgbado ọkụ, na-ebelata corrosion electrochemical nke ọla kọpa na aluminom. Na mesikwuru ịgbado ọkụ oyi akwa ọbọp ọgwụgwụ ihu nke aluminom conductors nke mere na ọla kọpa ọnụ na eduzi isi agaghị abata kọntaktị na ikuku na mmiri mmiri, n'ihu mbenata corrosion. Na mgbakwunye, oyi akwa ịgbado ọkụ mgbanwe na oyi akwa ịgbado ọkụ siri ike na-edozi ọnụ ụzọ ọla kọpa na nkwonkwo waya aluminom, na-abawanye ike ndọpụ nke nkwonkwo na-eme ka usoro nhazi dị mfe. Agbanyeghị, ọghọm dịkwa. Ngwa nke ịgbado ọkụ plasma na ndị na-emepụta eriri waya chọrọ akụrụngwa ịgbado ọkụ plasma raara onwe ya nye, nke na-enwechaghị ike ma na-abawanye itinye ego na akụ nke ndị na-emepụta eriri waya. Nke abụọ, n'ime usoro ịgbado ọkụ plasma, a na-emecha ihe na-ere ahịa site na capillary. Usoro ndochi oghere na mpaghara crimping bụ nke a na-achịkwaghị achịkwa, na-ebute àgwà ịgbado ọkụ ikpeazụ na-akwụghị ụgwọ na mpaghara njikọ ịgbado ọkụ plasma, na-ebute nnukwu ọdịiche na arụmọrụ eletriki na ígwè ọrụ.

Oge nzipu: Feb-19-2024